FAQs

Got questions? We’ve got answers. Whether you’re curious about our capabilities, lead times, materials, or how we work, this page covers the most common questions we get from engineers, designers, and innovators. If you don’t see what you’re looking for, don’t hesitate to reach out—our team is here to help.

We are fully licensed and registered for all your manufacturing needs.

We are fully licensed and registered for all your manufacturing needs.

FREQUENTLY ASKED QUESTIONS

-

To provide a quote for a custom part, we primarily need a CAD file; STEP files are preferred as they are the least prone to scaling issues. Drawings specifying threaded holes, tolerances, or special features like engraving locations are also required.

-

In short, no. As part of our workflow and quality control system, we do not accept customer-supplied materials. Material selection directly affects workholding, machining strategy, and process control, all of which are critical to achieving consistent quality and efficiency.

-

No. We do not modify customer-supplied parts, including parts produced by other shops. This policy is driven by liability considerations and because our processes are optimized for manufacturing new parts to controlled specifications rather than modifying existing components.

-

We machine a wide range of metals including aluminum, steel, stainless steel, copper, brass, and titanium. We also work with select engineering plastics such as Delrin, PEEK, HDPE, and Ultem. However, we do not machine wood, G10, carbon fiber, foam, or graphite.

-

While we're thrilled to be part of your creative process, we don't engage in design or engineering work. However, we're more than happy to review your drawings and CAD files to provide feedback that could help reduce machining costs.

-

Our standard lead times vary based on material availability, required outside processes, and current workload. For the most accurate and up-to-date estimate, please email your project requirements along with your desired delivery date so we can review and provide a timeline.

-

We strive to meet our customers’ needs and will consider rush orders on a case-by-case basis. Approval depends on current workload and material availability. Please contact us directly to discuss any urgent requirements.

-

Yes, we are happy to support the prototyping phase of your project. To proceed, we require STEP files and drawings to ensure the components meet your specifications.

-

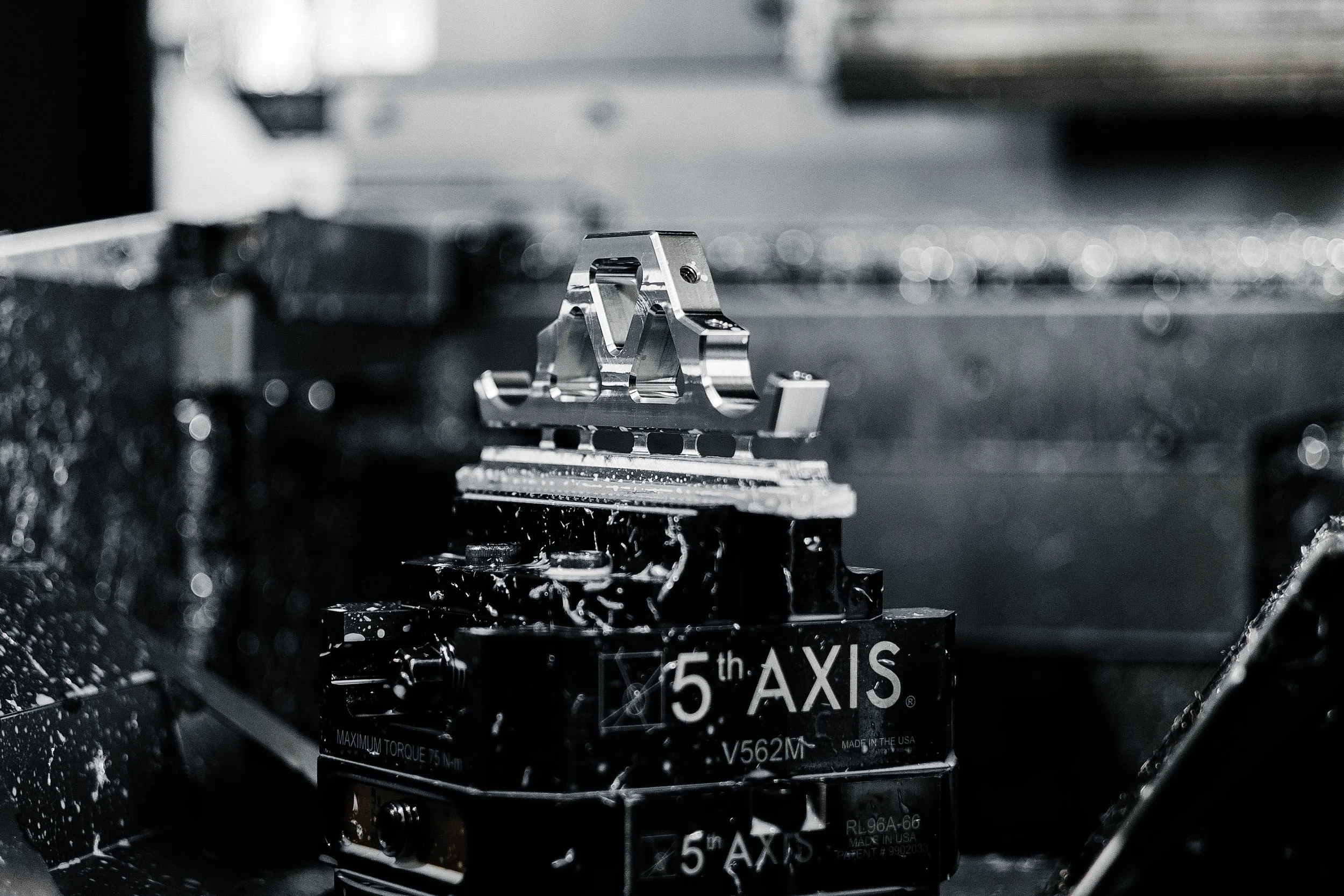

Method MFG is an ISO 9001:2015 and AS9100D–certified manufacturer. Our quality system is designed to support the production of flight-critical components, including parts currently operating in space and supporting human spaceflight missions.

-

Certainly. In-house, we provide Type II clear and Type III black anodizing. For finishes beyond these, we collaborate with reputable external vendors to ensure your parts meet the desired specifications.

-

We pride ourselves on flexibility, leveraging advanced software and robotic automation. There is no minimum order quantity, whether you need a single part or high-volume production running 24/7 in lights-out automation, we’re equipped to support your machining needs.

Have a question not on the list?

Please don’t hesitate to reach out and ask.